Sampling systems

We specialize in supplying leading edge equipment in process flow control solutions that address and exceed our customers’ needs to enable them to operate better, faster and safer. We offer a comprehensive range of sampling systems, products and solutions

Products range as below:

Gas sampling system (Dopak S32 G)

Liquefied gas sampler with externally coupled valves (gearbox) to take representative samples of liquefied gases or liquids. The Dopak 32-LG type samplers are built from high quality stainless steel. Installation by means of threaded connections, compression fittings or flanges. Systems can also be be offered with a range of sample cylinders including those with outage tubes. outage.

Again simple to operate with just a single handle operation, providing a perfectly safe sample for the operator and the environment. The Dopak S32-LG type samplers are supplied as standard with a manual handle but a spring return handle is a possible option and improves operator and process safety. Purge options are again available.

Suitable for the following process application;

- Predefined fixed volume sample volume

- Closed vent sampling of liquefied gas (LG)

- Use an expansion chamber rather than outage tube

- High vapour pressure liquids

- Zero quick connect vapour release (QC couplings)

Sampling systems for hazardous chemicals

Dopak manual industrial sampling systems for hazardous chemicals improve safety and reduce spills because they use the patented Dopak needle assembly – feel free to contact us to discuss the details.

Hazardous chemical industrial sampling systems from Dopak are installed worldwide in all sectors of the process industry and these can be installed to a pipeline or to a tank. The sampling connection in oil and gas applications can be very similar to connections in petrochemical, chemical or even pharmaceutical applications. We have standard connections available to suit all industrial sampling applications.

With a Dopak sampling system you can take a hazardous flowing liquid sample safely and cleanly with no spills using our septum sealed sample bottles. Below are details of types of sampling in analytical chemistry from Dopak, take a look and get in touch for datasheets, price and delivery details;

Low pressure liquid sampling system (Dopak DPM)

Liquid sampler to take accurate samples of hazardous liquids with low vapour pressure at low process pressure (<8 bar). This DPM type sampler is built from high quality stainless steel 316. Installation can be either a threaded connection, compression fittings or flanges of your choice. Simple to operate systems with one just handle operation providing perfect safety for the operator and the environment. You can also introduce nitrogen or solvent purges to keep the sampler clean and to ensure representivity.

Suitable for the following process application;

- Liquids at lower pressure (Less than 8 bar)

- Closed sampling with lower vapour pressure (Less than 0.7 bar)

- Corrosive and hazardous liquids

- Sampling is possible from both pipelines and tanks

- Zero emission, no spill sampling

Heavy duty and fire safe hazardous chemical sampling systems (Dopak HD)

Liquid sampler to take representative samples of liquids with low vapour pressure at low process pressure (less than 8 bar). This sampler uses a sample probe. The HD type sampler is a pipe specification sampler built from high quality stainless steel. Installation using a flange. Simple to operate samplers with one handle operation providing perfect safety for the user and the surrounding environment. The Dopak D type samplers always have a spring return lever.

Suitable for the following process application;

- Liquids at lower pressure (Less than 8 bar)

- Closed Sampling with lower vapour pressures (Less than 0.7 bar)

- Corrosive, hazardous liquids

- Sampling from both pipelines and tanks

- Fire safe anti-static process sampling valves

- Zero emission sampling, no spills!

Piston valve sampling system (Dopak DPJ)

Liquid sampler to take representative samples of viscous liquids by using a piston valve. The outlet of the sample valve can be purged giving zero dead volume and a clean sampler after every sample taken! The Dopak DPJ type sampler is built from high quality stainless steel 316. Installation is by means of threaded connections or flanges. Simple operation samplers providing perfect safety for the operator and the environment. Purge is with nitrogen, steam or solvent for perfect cleanliness every time.

Suitable for the following process application;

- Liquids at both low and high pressure

- Closed sampling with lower vapour pressure (Less than 0.7 bar)

- Fixed volume sampling

- Corrosive, hazardous liquids

- (High) Viscous fluids and slurry applications

- Zero emission sampling from any pipes, tanks and reactor vessels

- Sampling under vacuum conditions is possible

- For high temperature applications a cooling jacket can be included also.

Inline sampling system (Dopak DPT)

Liquid sampler to take representative samples of liquids with low vapour pressure at low process pressure (less than 8 bar) by using in-line sample valves. The Dopak DPT type pipe specification samplers are built from high quality stainless steel. The sample valve is available in both wafer type (for installation between flanges) or flanged type.

Simple to operate, safe sample every time. Single spring return lever is a great option providing optimum safety for the operator and the local environment. The Dopak DPT type samplers are standard equipped with a manual hand wheel. Other handles are optionally available.

Suitable for the following process application;

- Liquids at lower pressure (Less than 8 bar)

- Closed Sampling with lower vapour pressure (Less than 0.7 bar)

- Inline closed liquid sampling

- Corrosive hazardous liquids

- Zero emission sampling from horizontal or vertical pipelines

High pressure, fixed volume hazardous chemical sampling systems (Dopak S23)

Liquid sampler with internally coupled valves (connecting rod) to take fixed volumes of liquids with low and/or high vapour pressure independent of process pressure and with zero dead volume. The Dopak System 23 type sampler is built from high quality stainless steel. Installation by means of threaded connections, compression fittings or flanges.

Simple to operate, no training required. Safe sampling of hazardous chemicals with one handlen providing optimum safety for the operator and the environment. The System 23 type samplers have as standard a manual handle but the spring return handle is a common option to improve safety.

Suitable for the following process application;

- Liquid sampling at low and high pressure

- Closed vent sampling with low and high vapour pressure

- Fixed volume sampling

- Corrosive, hazardous liquids

- Zero emission sampling direct from pipelines or across pump inlet/discharge from reactors

- Sample sizes from 1cc to 2000cc and beyond!

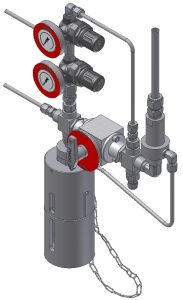

Vacuum and vessel sampling system (Dopak S32)

Liquid sampler with externally coupled valves (gearbox) to take representative samples of liquids from reactors at vacuum conditions or fixed volume samples of fluids with low vapour pressure independent of process pressure. The Dopak system 32 samplers are built from high quality stainless steel 316 and installation is by either threaded connections, compression fittings or flanges.

Simple to operate, one handle operation, perfect safety for the both the user and the local environment. The System 32 sampler is supplied with a standard manual handle but again spring return handles are a possible option.

Suitable for the following process application;

- Liquid Sampling at low and high pressure

- Closed sampling with lower vapour pressure (Less than 0.7 bar)

- Corrosive, hazardous liquids

- Zero emission sampling from process pipelines or from the top of reactor vessels