Flow Control Equipment

In Oil & Gas industry processing , We can offer a wide range equipment for Fluid or gas flow can be controlled using various equipment such as valves, pumps, and flow meters….etc

List of equipment we can provide are as below :

1- Valves

Valves are mechanical devices that control the flow and pressure of a fluid in a hydraulic or air system. They are essential components of pipe systems that transport liquids, gases, vapors, sludge, etc.

There are many different types of valves are available, each one has different characteristics, capacity and uses. There are different operation methods available: manual, pneumatic, electric, etc.

Applications : Chemical Processing , Oil Processing , Liquid Gases and Steam

SIZE RANGE : ½“ – 80“

PRESSURE RATINGS : Class 150 – 4500

TEMPERATURE RANGE : -40°C up to 500°C

MATERIALS OF CONSTRUCTION : Can be customized according to customer requirements

RANGE OF VALVES : Ball valves , Gate valves , Butterfly valves , Globe valves , Regulating valves , Check valves , Release valves , Manifolds , Solenoid valves , Valve actuators ….etc

2- Pumps

Applications : Chemical Processing , Oil Processing , Industrial , Feedwater

MATERIALS OF CONSTRUCTION : Can be customized according to customer requirements

PUMPS RANGE : Water pumps , Chemical pumps , Air pumps , Centrifugal pumps , Pumping units , Pumping stations ….etc

3- Pipes, Tubes and Fittings

Applications : Chemical Processing , Oil Processing , Industrial , Feedwater

SIZE RANGE : ½“ – 80“

TEMPERATURE RANGE : -40°C up to 500°C

MATERIALS OF CONSTRUCTION : Can be customized according to customer requirements

RANGE : Pneumatic fittings , Hydraulic fittings , Quick couplings , Tube fittings , Flanges , expansion joints , Pipes , Hoses ….etc

4- Flow , Pressure and Level Measurement :

Flow, Pressure and Level Measurement equipment , is essential for most industrial processes,As is often the case, there are several measurement technologies available. In order to choose the right technology.

Product range as below :

– Flow sensor .

– Flow transmitter .

– Flow meter .

– Flow meters .

– Pressure gauges .

– Pressure switches .

– Level gauges .

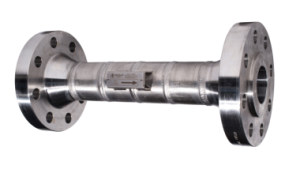

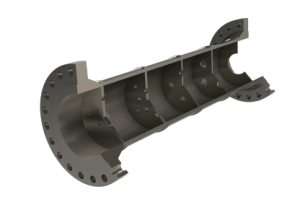

5- RESTRICTION ORIFICES :

The function of a restriction orifice is to limit a flow rate or to reduce a pressure in a pipe. It is calibrated according to the technical specifications of the installation so as to reach the desired pressure or flow rate; according to the values to be achieved, either simple restriction orifices (single-hole or multi-hole) or multi-stage restriction orifices can be proposed.

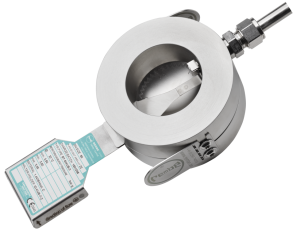

6- Rupture Discs :

Rupture discs are high precision safety devices that incorporate state-of-the-art technology. They are individually manufactured and tested for every application. When the pressure reaches a pre-defined limit the rupture disc opens to relieve the system. Rupture discs can be used as either a primary or secondary relief devices. They can also be used in combination with safety valves. The advantage here is that the valve is protected against contamination by the product or corrosion damage. This is often an attractive and cost-effective option.